About Us

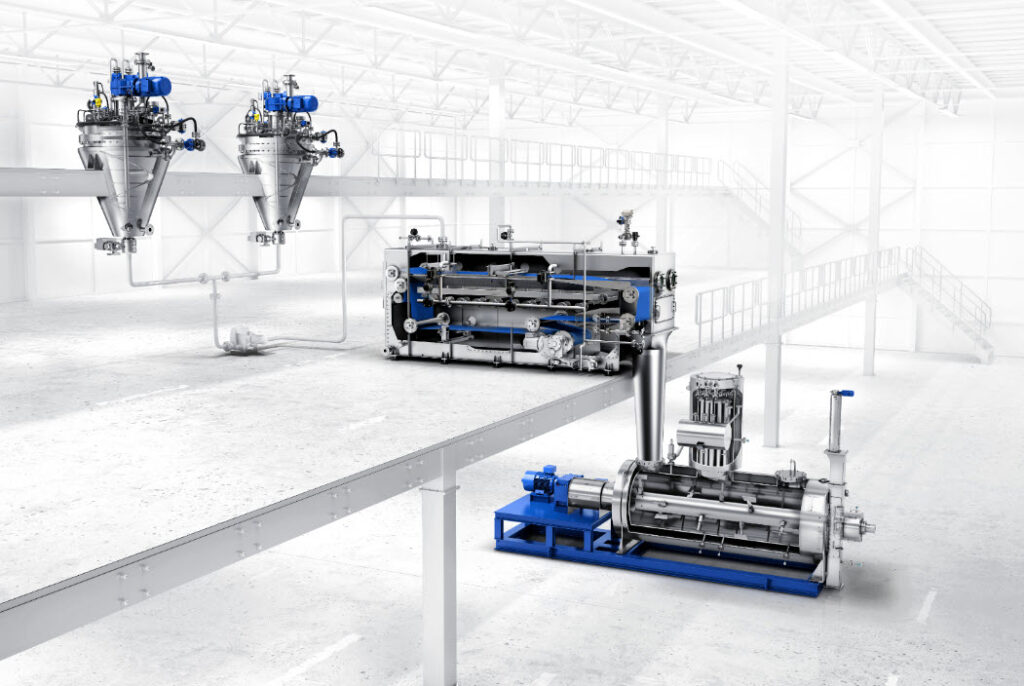

At BHS-Sonthofen Inc. we provide best-in-class European machinery matched with our American Spirit. Our customer service driven mentality and ability to provide innovative solutions allows our customers to reach their production goals.

BHS-Sonthofen Inc. serves as the North American subsidiary for the German based BHS-Sonthofen group. Founded in 1998, we have a long history of providing world-class service and support to local customers. Our state-of-the-art facility located in Charlotte, NC features a 10,000 sqft warehouse stocked with parts and rental equipment, as well as an in-house laboratory designed for filtration process development.