Process Engineering

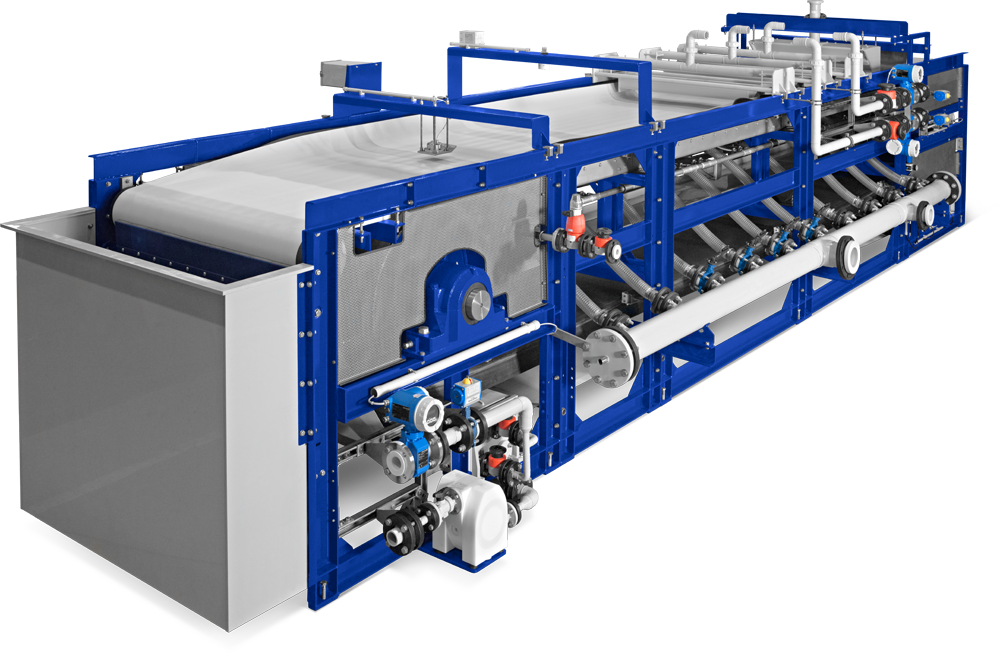

Rubber Belt Filter

Description

The BHS Rubber Belt Filter is a continuous vacuum filtration system designed for cake washing and drying of high-solids slurries. It features a filter cloth supported by a rubber, EPDM, or synthetic drainage belt. Filtrate tubes separate the filtrates into dedicated receivers for recovering mother liquor, wash filtrates, counter-current washing, and drying gas. The drainage belt moves on specially coated rollers, eliminating the need for air and water sliding systems.

The roller-supported belt enables fast filtration and large filter areas, up to 200 m², ideal for handling heavy cakes. The system can also integrate steaming and counter-current washing as part of the design.

Animation

Technical Specifications

| Type | Active filter width | Active filter length | Active filter area | Motor power | Dimensions | Weight | ||

|---|---|---|---|---|---|---|---|---|

| Length | Width | Height | ||||||

| BFR 120 | 1.050 mm | 6 – 10 m | 6 – 11 m² | bis 11 kW | 9,5 – 13,5 m | 2,2 m | 2,3 m | 3 – 10 t |

| BFR 160 | 1.450 mm | 8 – 14 m | 12 – 20 m² | bis 15 kW | 11,5 – 17,5 m | 2,6 m | 2,3 m | 4 – 15 t |

| BFR 200 | 1.850 mm | 10 – 18 m | 18 – 33 m² | bis 18,5 kW | 13,5 – 21,5 m | 3 m | 2,3 m | 6 – 20 t |

All specifications apply to the standard version.

Technical data for customized designs may differ from the specified data.

All technical data may change due to development.

Subject to modification without notice.

| Operating method | continuous |

|---|---|

| Operating pressure | vacuum |

| Operating temperature | up to 90 °C |

| Solids content (suspension) | up to 60 % (by weight) |

| Cake thickness | up to 80 mm |

| Grain size | 10 – 500 µm |

| Filter output – suspension | up to 15 m³/m²/h |

| Filter output – dry solids | up to 5.000 kg/m²/h |

| Active filter surface | 6 – 33 m² |

Pilot Test Filter

Pilot BFR and Filtrate Skid

- Active Filter Area: 0.9m²

- Dimensions (LxWxH): 17.5ft x 6ft x 5.5ft

- Material of Construction: SBR Rubber and Polyethylene

- Vacuum Filtrate Skid Dimensions: 7.5ft x 5ft x 7ft