Process Engineering

Pressure Plate Filters

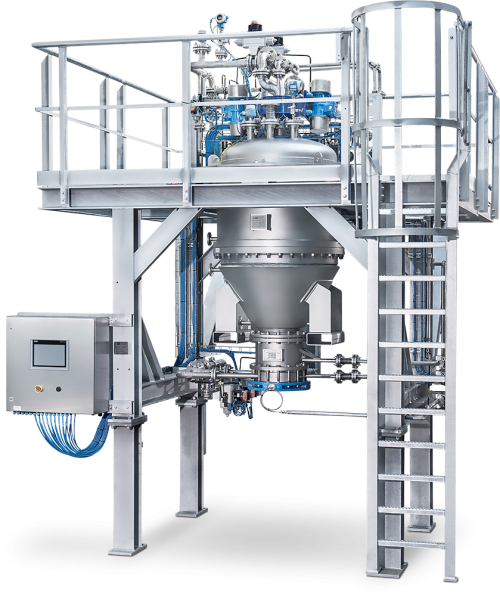

Description

The BHS Pressure Plate Filter provides for thin-cake batch filtration, cake washing, drying, reslurry and automatic cake discharge as well as heel filtration in a pressure vessel. Cake can be discharged as dry cake, wet cake or a concentrated slurry. Units are available from 0.35 m² to full production models. Pressure Plate Filters are installed for clarification and recovery applications from liquids with low solids content ranging from 5% to PPM levels.

The BHS filter plates are sloped and formed into a plate-stack which eliminates the bypass of solids or liquids. For cake discharge, two motors, typically 1 HP or less, gently vibrate the plate stack causing the solids to move along the plates to the vessel wall and out of the bottom. The BHS design eliminates rotating plates, gear boxes, and mechanical seals for a low-maintenance operation.

Materials of construction are stainless steels and alloys. The filter media is a synthetic polymer or metal with a clean removal efficiency to 0.5 microns. As the cake builds up, removal efficiencies improve to less than 0.5 microns. Filter aid and activated carbon can also be used.

Animation

Technical Specifications

| Type | Plate diameter | Filter area/plate | Number of plates | Active filter area | Vessel diameter |

|---|---|---|---|---|---|

| PF 04 | 400 mm | 0,11 m² | 3 – 6 | 0,33 – 0,67 m² | 550 mm |

| PF 07 | 760 mm | 0,42 m² | 4 – 15 | 1,7 – 6,3 m² | 1.000 mm |

| PF 10 | 1.010 mm | 0,78 m² | 7 – 30 | 5,5 – 23,4 m² | 1.300 mm |

| PF 14 | 1.440 mm | 1,5 m² | 16 – 30 | 24 – 45 m² | 1.800 mm |

All specifications apply to the standard version.

Technical data for customized designs may differ from the specified data.

All technical data may change due to development.

Subject to modification without notice.

| Operating method | intermittent |

|---|---|

| Operating pressure | up to 10 bar (g) |

| Operating temperature | up to 250 °C |

| Solids content (suspension) | up to 10 % (by weight) |

| Cake thickness | up to 60 mm |

| Grain size | from 0,5 µm |

| Filter output – suspension | up to 4 m³/m² h |

| Filter output – dry solids | – |

| Active filter surface | 0,35 – 45 m² |

Pilot Test Filter

PF04

- Active Filter Area: 0.69m²

- Dimensions (LxWxH): 3ft x 3ft x 5.5ft

- Maximum Operating Pressure: 6 barg (87 psi)

- Material of Construction: Stainless Steel