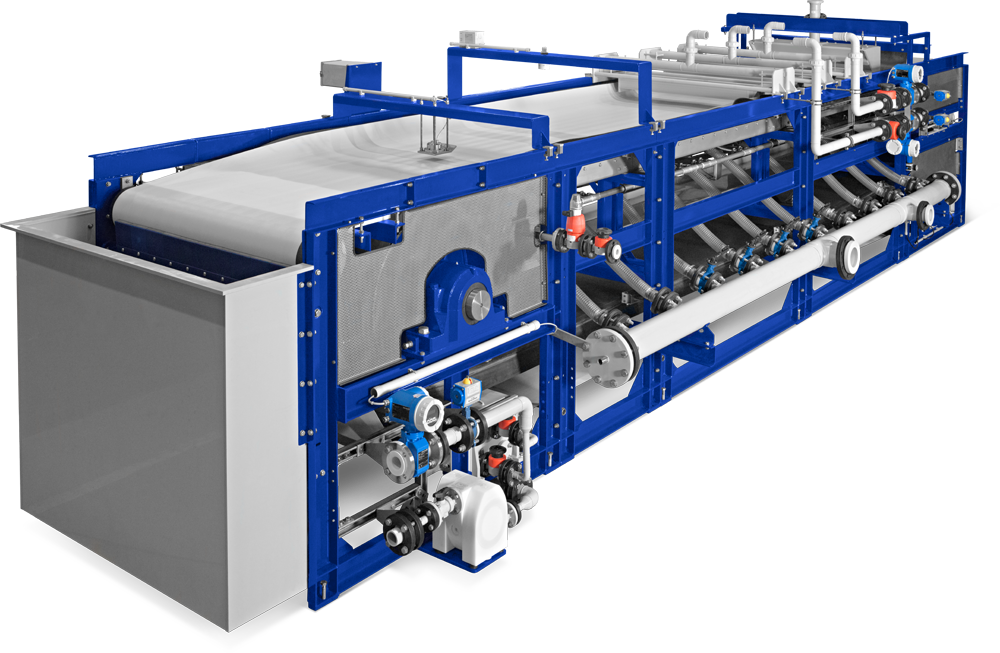

General Description

The BHS Rubber Belt Filter is a continuously operating filter for vacuum filtration, cake washing and drying of high solids slurries. The technology is based upon a filter cloth supported by a drainage belt made of rubber, EPDM and other synthetic materials. Individual filtrate tubes separate the filtrates into specific receivers for recovering of mother liquor, wash filtrates, counter-current washing and drying gas. The drainage belt travels on specially-coated rollers eliminating air and water sliding systems.

The roller-supported drainage belt allows for fast filtration and large filter areas up to 200 m² for heavy cakes. Steaming as well as counter-current washing are able to be integrated into the design.

Animation

PILOT TEST FILTER

Pilot BFR and Filtrate Skid

-

Active Filter Area: 0.9m²

Active Filter Area: 0.9m² -

Dimensions (LxWxH): 17.5ft x 6ft x 5.5ft

-

Material of Construction: SBR Rubber and Polyethylene

-

Vacuum Filtrate Skid Dimensions: 7.5ft x 5ft x 7ft

Download Data Sheet

Articles

Quick Help

Applications

- Flue gas desulfurization

- Minerals & zeolites

- Fly ash

- Organic Chemical

- Industrial Waste

- Food & Feed Products

- Pulp Washing

- Tar Sands

- Steel Mill Waste

- Agrochemicals

Special Designs

- Flexible Belt Materials of Construction

- Co-current washing

- Counter current washing

- Easy wear belt maintenance

- Variable speed control by cake height monitoring

- Fume hood

- Cake discharge chute