Articles

BHS Continuous-Indexing Vacuum Belt Filter

© 2024 —BHS SONTHOFEN. All Rights Reserved. BHS-Sonthofen Inc. • 14300 South Lakes Drive, Charlotte, North Carolina 28273-6794 • Phone: 704-845-1190 • Fax: 704-845-1902

BHS-Sonthofen Inc. • 14300 South Lakes Drive, Charlotte, North Carolina 28273-6794 • Phone: 704-845-1190 • Fax: 704-845-1902

General Description

The BHS Continuous-Indexing Vacuum Belt Filter provides for vacuum filtration, cake washing, pressing and drying of high solids slurries. The technology is based upon fixed vacuum trays, continuously feeding slurry system and indexing or step-wise movement of the filter media. In practical terms, the operational features of the Belt Filter can be viewed as a series of Buchner funnels.

For the process operation, due to the stepwise operation of the belt, washing and drying efficiencies are maximized with the stopped belt and the mechanism of “plug-flow” for gases and liquids. Cake pressing and squeezing further enhances drying. Finally, the fixed trays allow for the mother liquor and the wash filtrates to be recovered individually and recirculated/recovered/reused for a more efficient operation. Steaming as well as counter-current washing are able to be integrated into the design.

Animation

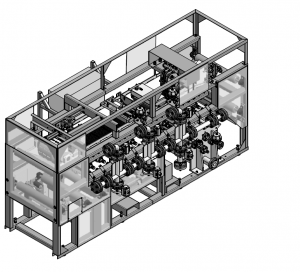

PILOT TEST FILTERS

Active Filter Area: 0.6 m²

Active Filter Area: 0.6 m² Active Filter Area: 0.5m²

Active Filter Area: 0.5m² Active Filter Area: 0.1m²

Active Filter Area: 0.1m² Dimensions (LxWxH): 8ft x 5.25ft x 6.5ft

Dimensions (LxWxH): 8ft x 5.25ft x 6.5ftArticles

© 2024 —BHS SONTHOFEN. All Rights Reserved. BHS-Sonthofen Inc. • 14300 South Lakes Drive, Charlotte, North Carolina 28273-6794 • Phone: 704-845-1190 • Fax: 704-845-1902