General Description

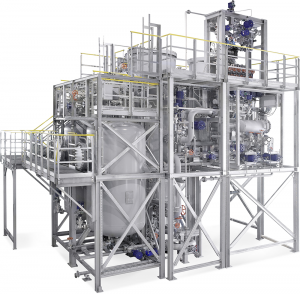

BHS delivers engineered packages for the BHS process filtration solutions.

In the “front-end” phase of a project, BHS identifies the filtration technology via lab and pilot plant studies. We scale-up and engineer the complete system including the feed pumps, tanks and transfer pumps, vacuum pumps, compressors, valves and instruments for a completely piped and wired skid with PLC controls. Solids handling with dosing, conveyors, storage and IBCs are also included.

In the “deliver” phase, we define the P & IDs, engineering specifications, manufacturing codes and schedules. Continuing in this phase is project execution including detailed engineering, 3D models, isometrics, ISA, motor and the required data sheets and process control descriptions.

In the final phase “operation” BHS provides the mechanical and process startup support as well as spare parts and continuous process improvements with the client.

BHS follows the RASCI approach to project systems (R = Responsible, A = Accountable, S = Supportive, C = Consulted and I = Informed). The result is a turnkey engineered package from BHS from slurry feeding to final product all on-time and within budget.

Turnkey Engineered Packages – Applications

- Specialty Chemicals

- Pharmaceuticals

- Hydrogenation reactions

- Catalyst Recovery

- Clarification

- Amine Scrubbing for CO2 & SO2

- Clarification

- Water Scrubbing

- Downstream of clarifiers

- Concentrating/Clarification

- Grey Water

- Gasification

- Bioenergy-Biochemical

- Brine and Chlor-alkali

- Glycol - MEG