General Description

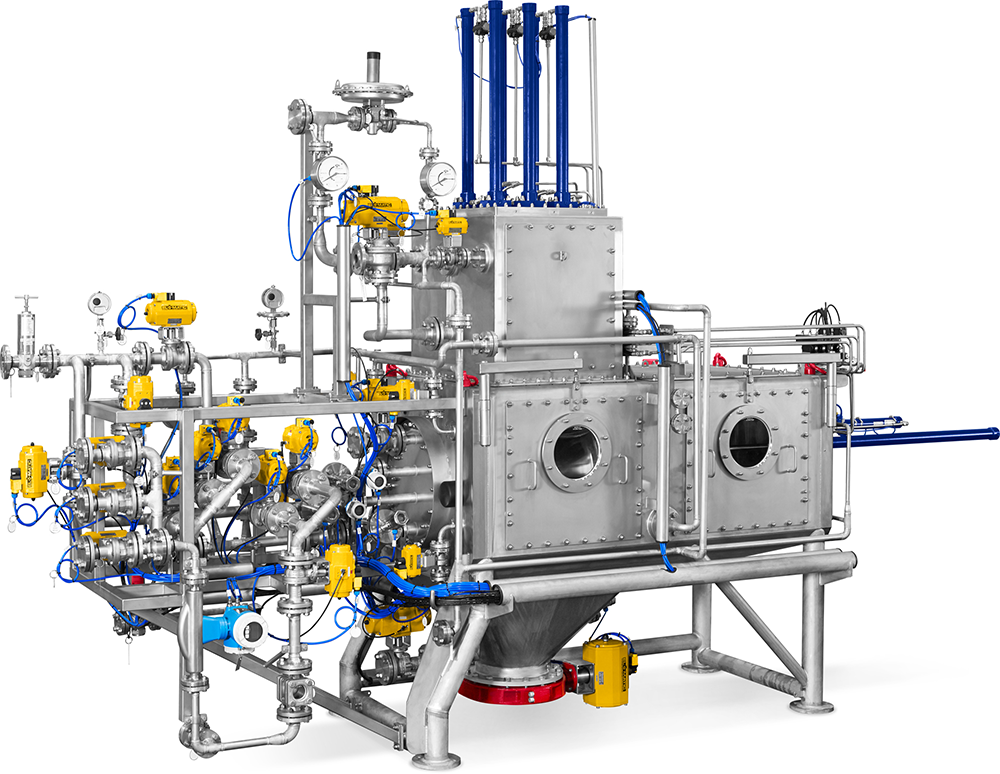

The BHS Autopress technology is a batch pressure filter operating similarly to a membrane filter press with the improved benefits of flow in the forward and reverse directions, no bypass of solids or liquids, complete containment and automatic cake discharge from a pressurized enclosure.

The Autopress technology consists of circular filter plates and flexible spacers for absolute plate-to-plate sealing. The movable filtration housing forms a pressure-tight seal up to 10 barg around the plate stack via a flexible membrane that is pressurized 1 – 2 bar over the operating process pressure. Automatic and contained discharge is via scraper knives.

The Autopress provides for reproducible cake thickness which results in a validated cGMP process operation. The cake can be filtered, washed in the forward and reverse directions as well as dried by vacuum, pressure blowing and squeezing.

PLC control is via Batch S-88 standards and automatic Clean-In-Place (CIP) operation is to less than 1 ppm residual cross contamination passing riboflavin tests.

Animation

BHS Autopress

- Filter

- Complete Process

- Start/Closing

- Filtration

- Cake Washing

- Dewatering

- Pressing

- Opening

- Cake Discharge

PILOT TEST FILTER

AP300 Pilot Unit

-

Active Filter Area: 0.22 – 1.0m² (adjustable depending on test requirements)

Active Filter Area: 0.22 – 1.0m² (adjustable depending on test requirements) -

Dimensions (LxWxH): 7.5ft x 3.5ft x 8ft

-

Maximum Operating Pressure: 10barg (145psi)

-

Material of Construction: Stainless Steel or Polypropylene internals.

Download Pilot Unit Data Sheet

Articles

Quick Help

Applications

- Final Pharmaceutical Products

- Active Pharmaceutical Ingredients

- Specialty Chemical

- Pigments & Dye

- Precious Metal Recovery

- Activated Carbon Removal

- Toxic & Volatile Chemicals

Special Designs

- Flexible alloy and polymer materials of construction

- Cake compaction through hydraulic compression

- Clean in place (CIP) validation

- Steam in place (SIP)

- Ground and polished surfaces

- Pressure and vacuum drying capabilities

- Cake discharge into glove box

- Metal filter media